Organization and workflow on a job site is crucial to meeting deadlines on any roofing job. Natural Metal Associates specializes in Zinc installations on commercial and residential projects around the country. This blog will take a look at a high end residential project in Avalon, New Jersey to see how our tools are being put to use.

Project Details

- Installer: Natural Metal Associates (Contact: Louis Rondeau – Keith Rondeau – Mark Melone)

- Material: Architectural Zinc – .8mm Blue/Gray Rheinzink

- Size: 120 Square

- Residential new build in Avalon, NJ

- Double (180°) lock standing seam panels

- Crescent Eaves details

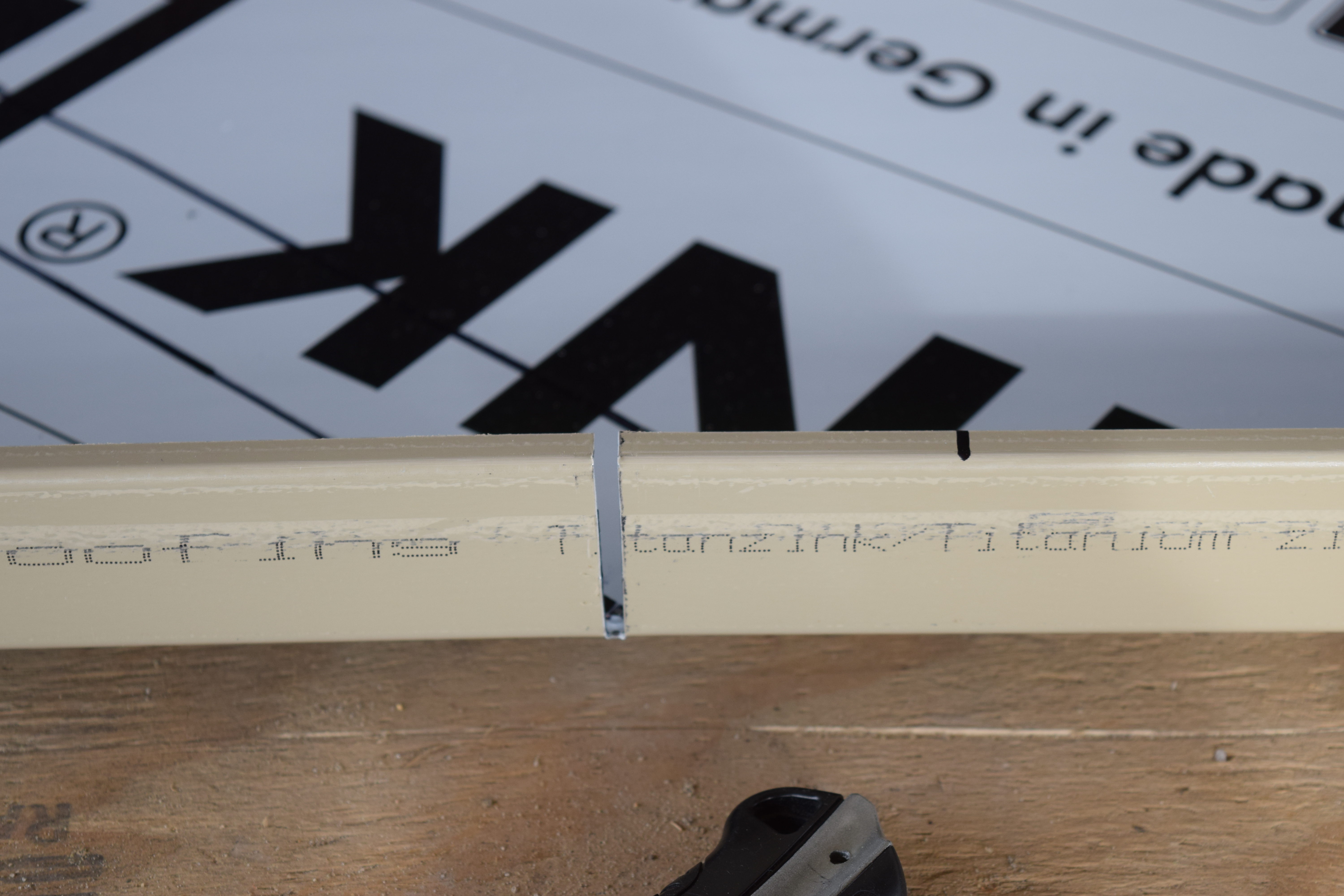

Preparing the Panels

The Rheinzink panels were all delivered to the job site prefabricated at 1.5″ height seams. Panels were trimmed to the proper taper and bread panned to fit underneath the hip caps.

In this scenario, panels were being prepped on the second story and then placed on “rack” attached to the lift. The lift then would raise to the 3rd story where the panel was installed and seamed.

Securing Panels

When the panel was properly laid into place, the clips were installed. Notice how the panel seam is slightly notched and folded over the clip to prevent any sliding.

Double Lock Seaming

In order to mechanically lock the 1.5″ panels, an ESE First Stage Seamer was used to complete the 90° fold. From then, the RAU117 Finish Hand Seamer can be seen folding the 180°. This tool is a strong and fast finish seamer. Additionally, the Biegetec Finish Seamer was tested on the material and did a great job closing both first and second locks of the panel while protecting the finish.

The recently released AccuSeamer was tested on the Zinc panels for both the 90° and 180° locks. The AccuSeamer performed without a hitch and as a result, the burden of hand locking every panel was relieved. One of the advantages of the AccuSeamer is the lack of transition marks that normally show on the panel from hand crimping.

Eaves Detail – Crescent Eaves

When you are installing a high end material like copper or zinc, the customer deserves attention to detail. The eaves edge of a seam should not be left open for water to pull into. The crescent eaves detail is a very smooth way of finishing the seam that is sure to give a refined look to the installation.

Pipe Boot Soldering

Ten separate pipes protrude from the roof decking. These pipes will have a prefabricated pipe vent seamed and soldered to the roof panels.

Choosing Rheinzink

Zinc roof and wall coverings are a great architectural choice if you are looking for a visually pleasing, long lasting, natural recyclable material. Zinc holds up well in coastal environments and has some specific characteristics that make it necessary to have a trained contractor complete the installation. Here are some Rheinzink advantages:

- Non-staining with clear run-off

- Non-toxic

- Malleable and capable of covering complex geometries

- Long lasting (Roof: 80-100 years Wall: up to 120 years)

- Looks fantastic – complements modern and traditional architecture

UPDATED PHOTOS