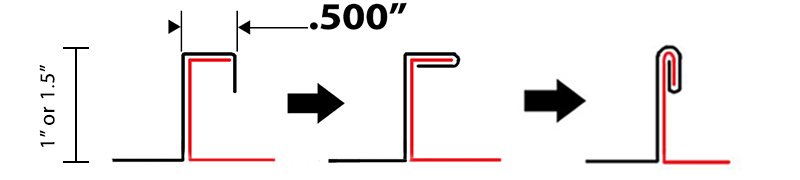

Mechanical lock panels are a tried and true part of the metal roofing industry. Long before snap lock profiles existed, metal workers were hand seaming panels together to achieve watertight roof surfaces. Rather than physically hammering seams into panels, now the industry uses preformed rolled panels that already have male and female profiles on them. These profiles utilize “mechanical lock seamers” to close the profiles and assure the roof will not leak.

What to know before buying – SEAM HEIGHT

Mechanical seams come in different sizes. Most common sizes for residential applications are 1″ and 1.5″ in height. Commercial panels often stand at 2″ in height and will often be rolled from thicker material.

1″ or 1.5″ Mechanical Lock Seams

Since the 1″ and 1.5″ mechanical lock seam is extremely common for residential applications, there are a variety of seamers that can complete the locking of this seam. Here are our recommendations below

2″ or Higher Mechanical Lock Seams

2″ or higher seams are most commonly found in commercial applications. The additional height of the seam raises the panel connection and gives less chance for water buildup, ice, or snow to seep into the seam. Not only is the 2″ seam taller, it more than not has widers dimensions on the other legs as well. The most common 2″ seam we see has a 3/4″ width on the female leg which limits the tooling options that can be used to close the seam. Often, 2″ seams will be 24 or 22 gauge in thickness.

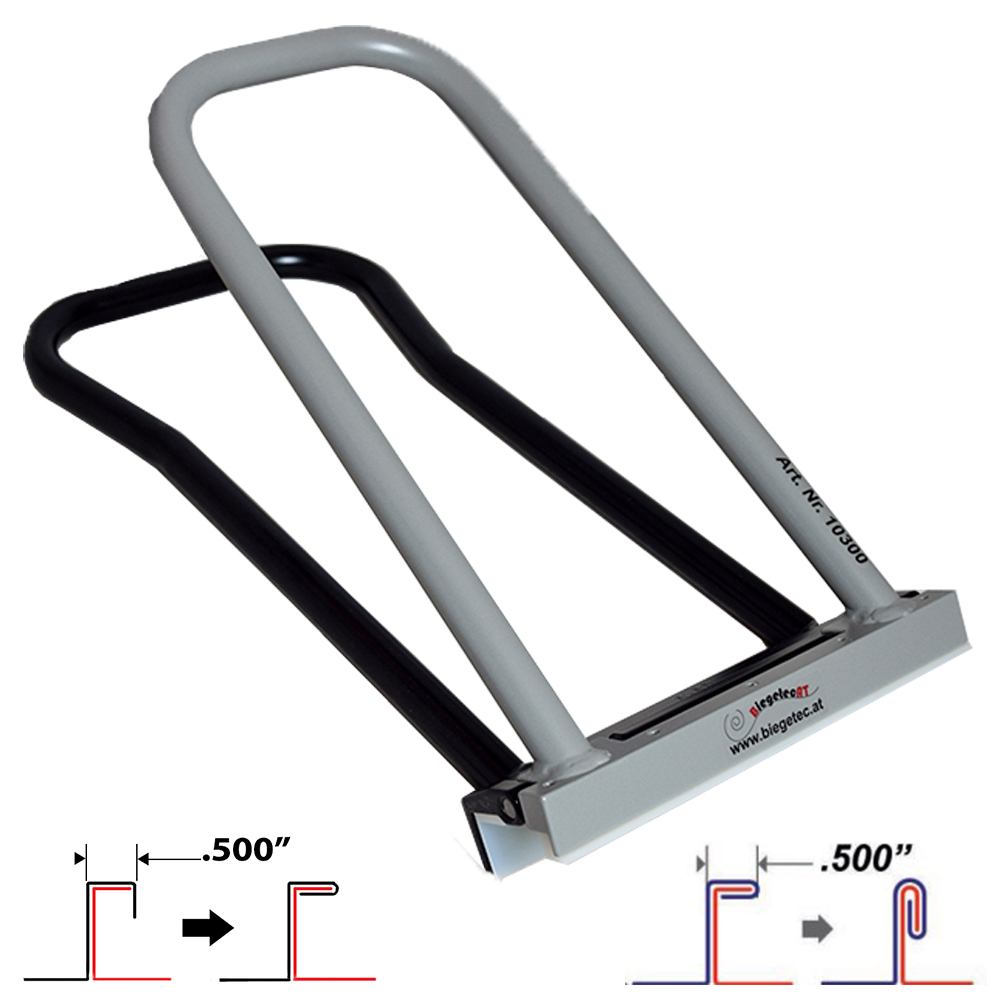

#1: Biegetec 2 in 1 Seamer

For best value and performance choose the Biegetec 2 in 1 Seamer. This tool is for closing the first (90°) and second (180°) locks of mechnical profiles. Here are the features:

- 2 tools in one – lightweight and easy to carry on roof

- Replaceable PVC jaws to prevent scratching. No other seamer we sell has this feature. It is HUGE if you are hand locking entire panels

- Tool if fast to use. Quick upright seaming keeps you off your knees and moving up the panel

- See more in use videos and testimonials on this product here

#2: ESE 001 & 099

ESE first and second stage closing tools are a staple in the US market for mechanical panels. They are durable and simple to use.

- ESE001Classic (90°) and ESE099 (180°)

- Built to last – durable construction for years of seaming without needing replacement parts

- Removable seaming handle – can be useful in tight seaming areas

- Foolproof use – Simple operation gets a perfectly closed seam everytime

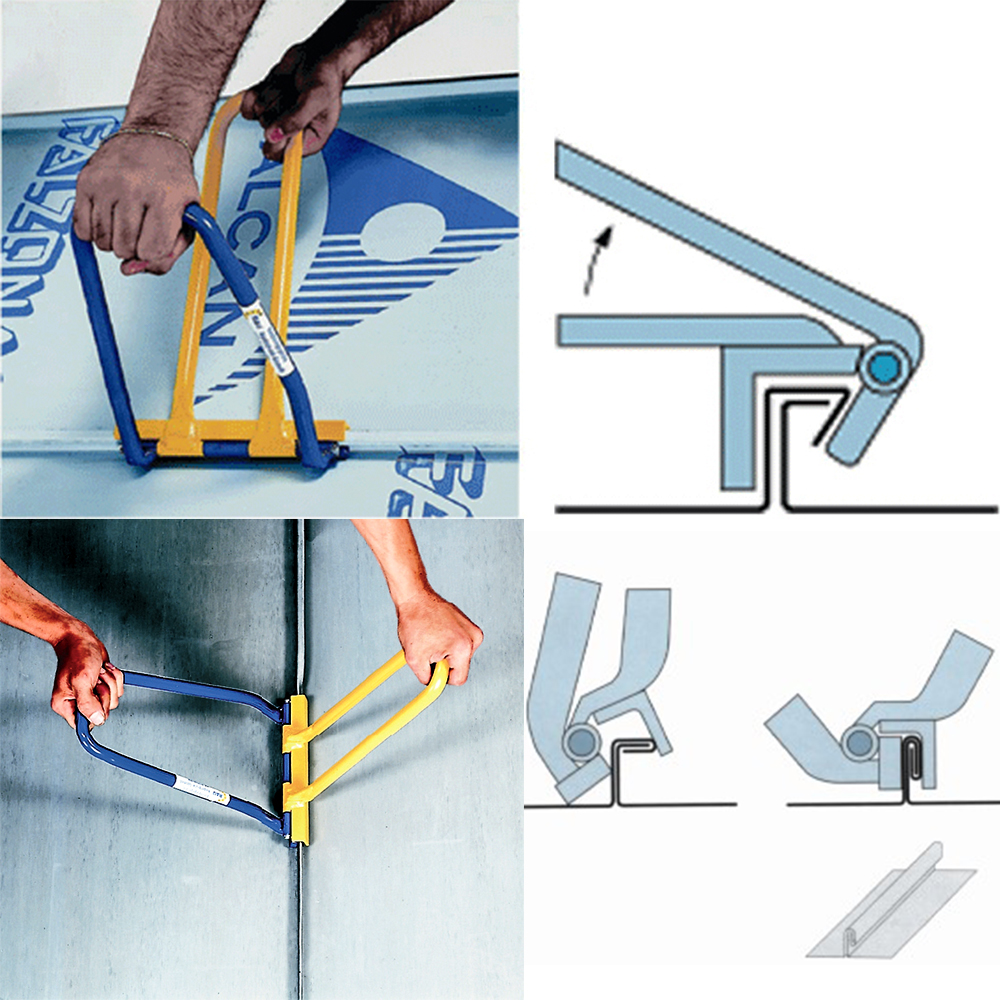

#3: RAU 111 & 117 Seamers

RAU seaming tools are high strength and high recognition with their bright blue and yellow color scheme

- Use the RAU111 for first stage (90°) closing

- Use the RAU117 for second stage (180°) closing. Combo sale price

- Separate tools for first (90°) and second (180°) stage seaming

- Long steel handles with durable welds make a high strength tool

- German manufacturing relied upon worldwide

While the RAU combo is not our lowest price, it is supremely reliable and depended upon by professionals worldwide. Their most popular product remains their Drip Edge Locking tool

#1: ESE001-750 & ESE099-750

For mechanical seams 2″ or higher, choices for manually locking the panels are limited. These panels have female profiles that vary in their width. This dimension is key in determining what tool will work properly. Many 2″ high seams will have a 3/4″ width on the female profile, but this still needs to be checked. Once verified, select the size from the ESE product page drop down options

- For first stage (90°) choose ESE001-Various Widths and match the female profile width size on the dropdown menu

- For second stage (180°) choose ESE099- Various Widths and match the female profile width size on the dropdown menu

- Long steel handles with durable welds make a high strength tool

- Made in USA

If you are set up correctly, you will only need these tools to get the seam closing started. You should be using an industrial power seamer to get the panel lengths locked together from there.